Canada Slot Websites There are over 50 LCD TVs and a 34 square metre LED screen, which means youll never miss any of the action. Casino That Accept Canada Express Very Well Casino offers generous bonuses for established players too. Free Casino Slots With Bonus

Bahis piyasasında adını duyuran bahsegel güvenilir altyapısıyla fark yaratıyor.

Kumarhane keyfini yaşamak isteyenler için güvenilir bahis siteleri kategorisi vazgeçilmezdir.

Türkiye’de oyuncular en çok Avrupa menşeli siteleri tercih eder, bahsegel apk bu güven düzeyine sahiptir.

Online oyun deneyimini yeniden tanımlayan Bahsegel kullanıcılarına eğlence sunuyor.

Kumarhane keyfini yaşamak isteyenler için bahsegel kategorisi oldukça ilgi çekici.

Kazanç elde etmek isteyen kullanıcılar için en uygun platform bahsegel olarak bilinir.

Online bahis dünyasında güvenli işlem garantisi sunan Bahsegel öncü markadır.

Bahis dünyasındaki tecrübesiyle fark yaratan bahsegel güvenle büyüyor.

Kumarhane eğlencesini seven oyuncular bettilt kategorisinde vakit geçiriyor.

Kazandıran bonus sistemleriyle bahsegel kullanıcılarını motive eder.

Kazançlı bonus fırsatlarıyla öne çıkan bettilt bahis dünyasında ses getiriyor.

Kullanıcıların hızlı erişim için en çok tercih ettiği yol bettilt sayfasıdır.

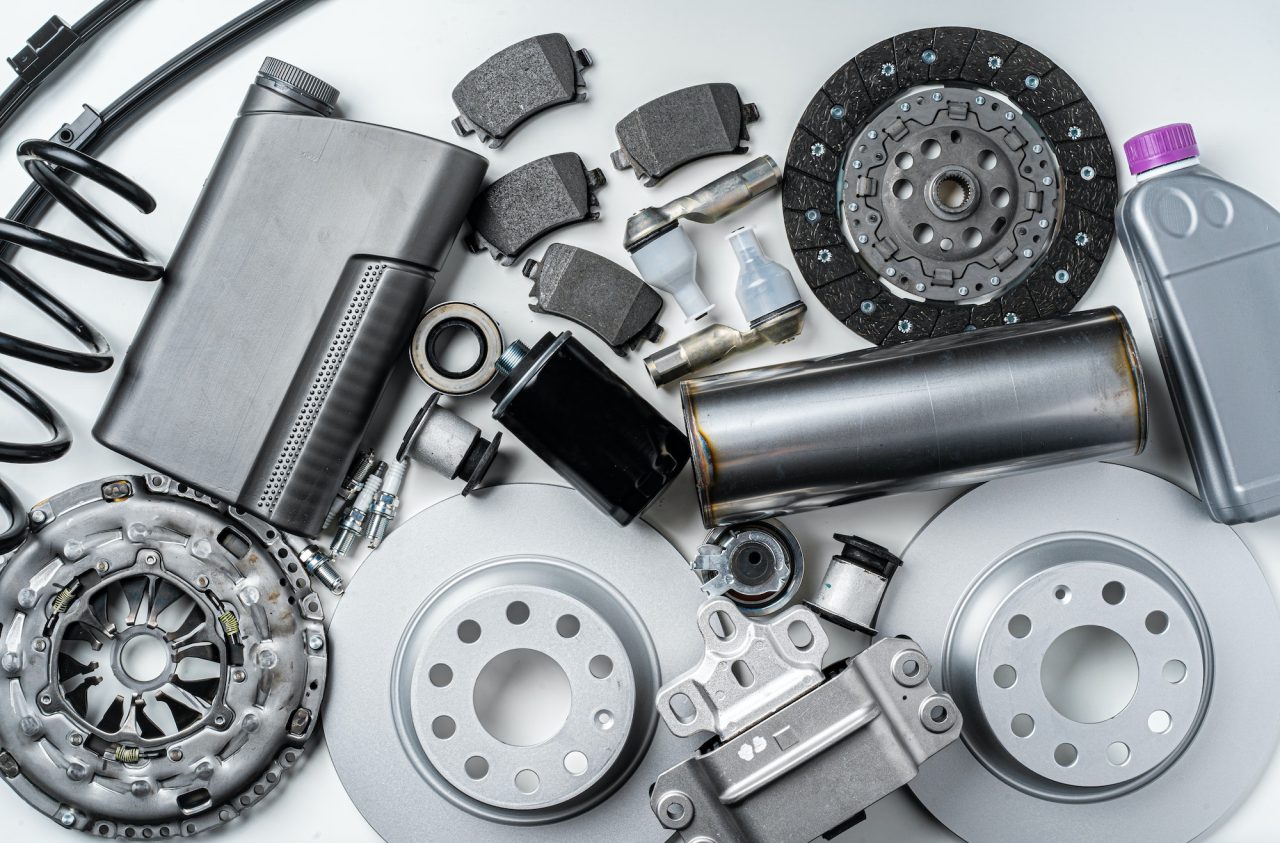

Dedicated to providing customers with automotive parts products and services

UNIVERSAL AUTOPARTS LTD Manufacturing Co., Ltd., registered capital: 10 million RMB, UNIVERSAL AUTOPARTS LTD has formulated a scientific development strategy according to national requirements and its own actual situation, actively focusing on the remanufacturing technology of high-end automobile brand engines, and introducing CNC processing equipment. At present, the products produced have fully covered many brands such as Mercedes-Benz, BMW, Audi, Land Rover, Jaguar, Volkswagen, Toyota, Nissan, Honda, Mitsubishi, Hyundai, etc. As a bright new star in the industry, since its establishment, it has always adhered to the “With the core concept of” building a brand with quality and innovating the future “, we continue to deepen the field of auto parts manufacturing, committed to providing customers with high-quality, efficient and reliable auto parts products and services.

The factory has a construction area of more than 4,000 square meters and an annual output of 4000 units. The company has developed into a comprehensive auto parts manufacturing enterprise integrating R & D, production and sales, and has grown into a star enterprise in the field of engine remanufacturing.

The rapid rise of the company has not only established a standardized engine remanufacturing plant in North China, but also successfully created a professional team composed of industry experts and technical backbones, laying a solid foundation for the company’s sustainable development.

Selected as a member unit of the "China Brand Innovation Development Project - China Brand Database

Invited by CCTV's "Quality China" program team to the UNIVERSAL AUTOPARTS LTD factory to film a documentary on engine remanufacturing, guiding the healthy development of the remanufacturing industry.

Obtain ISO 9001 "Quality Management System Certification".

Approved by the Beijing-Tianjin-Hebei Remanufacturing Research Institute and the China Automotive Industry Association, it has obtained the "Remanufacturing Management System Certification" and received unanimous recognition from the government and relevant institutions.

Become the designated product supplier for Beijing Youda Power Trading Co., Ltd.

Technological innovation is an inexhaustible driving force for the development of UNIVERSAL AUTOPARTS LTD Manufacturing Co., Ltd. The company has a strong R & D team, focusing on the R & D and innovation of auto parts technology, and constantly introducing new products that meet market demand

In order to improve high standards and quality, the company has acquired technical strength and provided strong support for brand building and market competitiveness.

In the production process, the company always follows the principle of high standards and strict requirements, and adopts advanced production technology and equipment to ensure the excellent quality of each product. Especially in the field of engine remanufacturing, advanced numerical control processing equipment and testing equipment are introduced for production and manufacturing, which are higher than the requirements of the original factory standard. Through the strict process of seven processes and four tests, it is ensured that the error of each part of each remanufactured engine cannot exceed one trace (one tenth of a hair), so as to control the product quality from the source, ensure that the performance and quality of each engine can meet or exceed the original new machine standards.

Advanced production process and equipment

Advanced CNC machining equipment and testing equipment

Strict testing process

Control product quality from the source

Know the importance of enterprise culture for enterprise development Adhering to the principle of "making products with human quality and winning the market with integrity" Create an honest, cooperative and win-win market environment

Concerned about environmental protection and sustainable development Implement a series of environmental protection measures to reduce environmental pollution in the production process Achieving a win-win situation between economic and ecological benefits

We will continue to adhere to the innovation-driven development strategy, continue to increase investment in research and development, and improve product quality and technical level. Expand domestic and foreign markets and jointly promote the prosperity and development of the auto parts manufacturing industry